In the grand tapestry of human progress, certain advancements operate in the background, invisible to the public eye yet fundamental to the marvels we celebrate. While headlines are dominated by sleek consumer gadgets and breakthrough pharmaceuticals, a critical discipline works tirelessly behind the scenes, ensuring these innovations are not only possible but also practical, safe, and efficient. This discipline is often encapsulated by the acronym FCAE, a cornerstone of modern engineering and design that is shaping the world around us in profound ways.

Table of Contents

Decoding the Acronym: What Exactly is FCAE?

FCAE stands for Finite Element Analysis in Engineering. To understand its significance, we must break down its components.

- Finite Element: This refers to a mathematical technique for solving complex problems by dividing a large, complicated system into a finite number of smaller, simpler parts called “elements.” Imagine trying to predict how a whole bridge will sway in the wind. Instead of analyzing the entire bridge as one impossibly complex object, engineers break it down into thousands of tiny, interconnected beams and blocks (the finite elements). Each of these simple elements is much easier to analyze mathematically.

- Analysis: This is the process of using mathematical models to study the behavior of these elements under various conditions, such as force, heat, vibration, or fluid flow.

- Engineering: This is the ultimate application. FCAE is not an abstract mathematical exercise; it is a practical tool used by engineers to simulate real-world physics before a single physical prototype is ever built.

In essence, FCAE is the computational simulation of how a physical product will react to real-world forces, using a digital model subdivided into a mesh of finite elements. It is a subset of the broader field of Computer-Aided Engineering (CAE), with FEA (Finite Element Analysis) being the specific analytical method at its core.

The Core Process: How FCAE Works in Four Stages

The application of FCAE is a meticulous process that transforms a digital design into a wealth of actionable engineering data.

1. Pre-Processing: Building the Digital Twin

This is the foundational stage. Engineers start with a 3D computer-aided design (CAD) model of the object, be it a bicycle frame, a smartphone casing, or an artificial heart valve. This solid model is then enveloped by a “mesh”—a network of small, interconnected elements (often tetrahedrons or hexahedrons) that collectively represent the object’s geometry. The quality of this mesh is critical; a finer mesh yields more accurate results but requires greater computational power. Finally, the engineer defines the material properties (e.g., steel, aluminum, plastic) and applies the anticipated loads and constraints (e.g., weight, pressure, fixed points).

2. Solution: Letting the Computer Compute

In this stage, the pre-processed data is fed into an FCAE software solver. The solver assembles and solves a vast system of algebraic equations for each element in the mesh, calculating how each tiny part responds to the applied loads. This process is incredibly computationally intensive and can take anywhere from minutes to days, depending on the complexity of the simulation and the power of the hardware.

3. Post-Processing: Interpreting the Rainbow

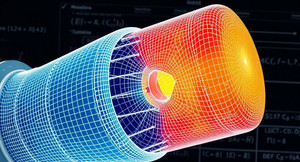

Once the solver completes its work, the raw numerical data is translated into visual results. This is where the iconic, colorful images associated with FCAE are generated. Engineers use color-coded stress maps, displacement plots, and animation tools to interpret the data. For example, a blue area on a component might indicate low stress, while a red area signals a critical high-stress zone that could lead to failure. This visual representation allows for intuitive and rapid identification of potential problems.

4. Validation and Iteration: The Cycle of Improvement

The initial results are rarely perfect. The FCAE process is inherently iterative. Engineers analyze the post-processed data, identify weaknesses or areas for optimization, and then return to the CAD model to make design changes. They might add material to a weak spot, remove it from an over-engineered area to save weight, or change the geometry altogether. The modified design is then put through the FCAE cycle again. This loop continues until the design meets all performance, safety, and efficiency criteria.

The Transformative Impact of FCAE Across Industries

The applications of FCAE are virtually limitless, touching nearly every field of engineering.

- Aerospace and Automotive: This is where FCAE truly shines. It is used to perform structural analysis on aircraft wings to ensure they can withstand extreme turbulence, crash simulation to enhance passenger safety, and thermal analysis on engine components. The relentless drive for fuel efficiency is achieved by using FCAE to lightweight components without compromising strength.

- Civil and Structural Engineering: Skyscrapers, bridges, and dams are all subjected to exhaustive FCAE simulations. Engineers can model how these massive structures will behave under seismic activity, high winds, and dynamic loads, ensuring public safety and structural integrity for decades.

- Biomedical Engineering: FCAE is revolutionizing healthcare. It is used to design and test prosthetic implants (like hip and knee joints) to ensure they can withstand the stresses of daily activity. Surgeons can use patient-specific FCAE models to plan complex surgeries, and biomedical engineers can simulate blood flow through arteries to design better stents.

- Consumer Electronics: The sleek, durable smartphones and laptops we use daily are products of extensive FCAE. Simulations ensure that a device can survive a drop, that it dissipates heat effectively from its processor, and that its components won’t fail due to vibration during shipping.

The Unmatched Advantages and Inherent Limitations

Advantages:

- Cost Reduction: Physical prototyping is expensive. FCAE allows for countless virtual prototypes at a fraction of the cost.

- Time Savings: The design cycle is dramatically shortened. Problems are identified and solved digitally, accelerating time-to-market.

- Enhanced Safety and Reliability: FCAE enables engineers to test products under extreme and dangerous conditions that would be impractical or unethical to test physically, leading to inherently safer designs.

- Optimization and Innovation: It empowers a “what-if” culture, allowing engineers to explore innovative designs and materials that might be too risky to pursue with traditional methods.

Limitations:

- Garbage In, Garbage Out (GIGO): The accuracy of an FCAE simulation is entirely dependent on the accuracy of the input data—the material properties, the loads, and the constraints. Incorrect assumptions lead to misleading results.

- Computational Cost: Highly detailed simulations of complex systems require significant computational resources and time.

- Expertise Dependency: Interpreting FCAE results requires a deep understanding of both the software and the underlying physics. An inexperienced user can easily misinterpret the colorful stress plots, leading to flawed design decisions.

The Future of FCAE: Integration, Intelligence, and Accessibility

The evolution of FCAE is moving towards greater integration and intelligence. We are seeing its convergence with other digital technologies:

- Generative Design: This is a symbiotic partner to FCAE. Algorithms generate thousands of design options based on goals and constraints, and FCAE is used to automatically test and validate each option, leading to organic, highly efficient structures that humans might not conceive of.

- AI and Machine Learning: AI can help automate the meshing process, suggest optimal solver settings, and even predict potential failure points based on historical simulation data, making the process faster and more intuitive.

- Cloud Computing: The power of FCAE is becoming more accessible through cloud-based platforms, allowing smaller firms to run sophisticated simulations without investing in massive local computing infrastructure.

Informational FAQs About FCAE

Q1: Is FCAE the same as CAD?

A: No, they are complementary but distinct. CAD (Computer-Aided Design) is used to create the geometric model of a product—its shape and dimensions. FCAE is used to analyze that model’s physical behavior—how it responds to forces, heat, etc. You typically need a CAD model to perform an FCAE.

Q2: What’s the difference between FEA and FCAE?

A: FEA is the specific mathematical method of breaking down a system into finite elements. FCAE is a broader term that emphasizes the application of FEA within the engineering process. In practice, the terms are often used interchangeably.

Q3: Can FCAE completely replace physical testing?

A: Not entirely. While FCAE can drastically reduce the number of physical prototypes needed, physical testing remains crucial for final validation. Physical tests provide real-world data that is used to calibrate and verify the accuracy of FCAE models.

Q4: What skills are needed to become an FCAE analyst?

A: A strong foundation in engineering mechanics (statics, dynamics, strength of materials), mathematics, and physics is essential. Proficiency with specific FCAE software packages and the ability to interpret complex data are also critical skills.

Q5: How has FCAE contributed to sustainability?

A: FCAE is a powerful tool for sustainability. By enabling lightweighting (using less material without sacrificing performance), it improves fuel efficiency in vehicles and reduces material consumption. It also helps optimize energy efficiency in systems like HVAC and power generation.